【PSC】AMSA 船舶滞留与缺陷的检查趋势总结

关于Tokyo MoU (AMSA)滞留与缺陷的检查趋势总结

a) Detainable deficiencies

FIRE SAETY

- Em’cy fire pump inoperative

- Engine room fire dampers wasted and not effectively closing

- Fire main isolation valve unable to be closed

- Local fire fighting water mist system for the machinery spaces defective

- Steering gear room ventilators defective and unable to close

- Remote quick closing valves for F.O settling tank defective

- Funnel fire damper defective

- Ventilator in bow thruster room defective

- Ventilators in cargo hold defective ISM- SMS as implemented onboard does not ensure vessel can effectively respond to emergency situations- ISM detainable deficiency on the basis of many deficiencies(Mostly engine parts related item such as AMS alarm, supply spare parts & etc.)- Enclosed space entry and rescue drill defective- Only one officer keeping navigation watch at night

- Not familiar with MARPOL(discharge food waste in prohibited area)

MLC(Working and Living Condition)- Crew had not been paid in accordance with employment agreement

- Breach of minimum rest hour

Life Saving Appliances- Lifeboat engine defective- Lifeboat engine exhaust pipe wasted/defective, leaking exhaust gas into lifeboat- Lifeboat on-load release mechanism defective- Steering system for water jet propulsion system of rescue boat defective

- Defective drainage bag of rescue boat

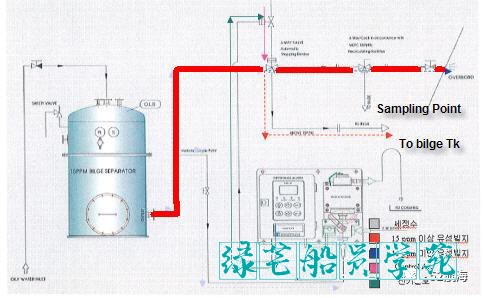

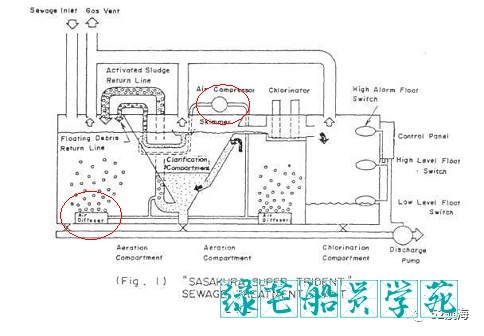

Pollution Prevention- Oily water separator 15ppm auto stop arrangement not operational- Oil discharged over ship side- Oily Water Separator defective due to abnormal condition of its 3-way valve- Sewage Treatment Plant defective due to abnormal condition of its pressure motor

- Sewage Treatment Plant return line malfunctional

ILL- Ballast tank air vent float ball defective- Means for securing weather tightness for No.1 hatch cover defective (cleat, rubber packing, washer, cleat pin)

- No.1 to No.5 cargo hold access hatch(total 10 nos booby hatch) all operating lever dogs/cams for closing found in seized condition. Access hatches unable to close and hatch cover is not weather tight.

Safety of Navigation- Latest charts not on board

- Crew unable to demonstrate operation of MF/HF on DC power

Others- Automatic starting of emergency generator not working- Failed to supply power to emergency switch board after starting emergency generator- Overall bad maintenance on board- Class Society not informed of various structural damage carried out by ship staff including repairs for cracks- Handrails and stanchions on forecastle missing (approximately 4~5m)- Main generators not properly maintained and unsafe to operate.- Statutory annual survey out of window. Not conducted.

- Fish room temperature +2 degrees C. Meat and fish stored in fish room. Meat and Fish not fully frozen and is soft to the touch.

b) Items to be inspected thoroughly

FIRE SAETY- Em’cy fire pump- Engine room fire dampers- Fire main isolation valve- Local fire fighting water mist system for the machinery spaces- Steering gear room ventilators

- Remote quick closing valves for F.O settling tank

ISM- Fully implementation of ISM- Satisfactory drills on enclosed space entry and rescue drill- MLC(Working and Living Condition)- Consistence in crew information between minimum crew certificate and labor contract

- Requirements of minimum rest hours

Life Saving Appliances- Battery of lifeboat engine in fully charged and ready for emergency use- Fixed eye for L/B embarkation ladder- No obstacles to liferafts for ready for immediate use

- Limit Switch for Rescue boat davit

Pollution Prevention- Familiarization with OWS (3 way valve and 15ppm alarm)- Check of any oil leakage from OWS- No Cooking oil discharged into the sea- Records of 15ppm bilge alarm- Operation of oily water separator and check for oil in discharge from the sampling line (please clean out the discharge pipe and filter)

- Sewage treatment operation (circulation line, hose between chambers, air compressor operation and pressure, air supply motor operation, installation of bio-filter etc.)

ILL- Load Line Marking, Air pipe, Ventilator, weather-tight door- Goose neck vent pipe for cargo hold- Hatch cover, Hatch coaming corrosion condition- Hatch cover rubber packing condition- Small hatches condition on deck

- Remote dewatering system

Safety of Navigation- Gyro repeater information can be seen from emergency steering position (close-up check during survey for new ship building)- VDR alarm, fire detection system, Inmarsat, EPIRB function test- Check of the latest charts and publications on board- BNWS in proper operation- Navigational lights- GDMSS Battery in fully charged and good condition

- S/G Alarm

ISPS

- Gangway watch

Others- Generator in proper condition and good operative- Keep class society informed when major deficiencies identified on board- Keep the relevant authorities timely informed when major deficiencies identified on board- Marking ECDIS as education & classification statement as appropriate- Handrails and stanchions in stable condition好了,以上即为本期关于AMSA滞留与缺陷的检查趋势总结, 感谢您的阅读!

- 发表于 2023-05-30 17:15

- 阅读 ( 373 )

你可能感兴趣的文章

相关问题

0 条评论

文件生成中...

请稍候,系统正在生成您请求的文件

【PSC】AMSA 船舶滞留与缺陷的检查趋势总结

扫码过程中请勿刷新、关闭本页面,否则会导致支付失败

购买后请立即保管好,30天后需重新付费。

【PSC】AMSA 船舶滞留与缺陷的检查趋势总结

扫码过程中请勿刷新、关闭本页面,否则会导致支付失败

购买后请立即保管好,30天后需重新付费。

请点击下载或复制按钮进行操作