化学品船氮气操作

应粉丝的要求,二师兄在这里分几天介绍化学品船的氮气操作和设备的操作程序。不论您轮是否有氮气发生器或氮气瓶,根据租家的要求船舶需要使用氮气来对货物进行维护,确保货物安全的运输。

氮气的操作有三种:

1. 惰化:

惰化的目的是防止形成爆炸性蒸气/空气混合物。对已用空气通风的货舱进行惰化时,应定期检查氧气含量。惰化后的氧含量不应超过体积比的 5%,通常应在 2% 左右,以防止分布不均。遇氧反应性货物(例如丁二烯)可能需要低得多的氧含量。在此操作期间必须达到要装载的特定货物的露点温度.

INERTING:

The purpose of inerting is to prevent the formation of explosive vapour/air mixtures. When inerting a tank

which has been ventilated with air, the oxygen content should be checked regularly. The oxygen content

after inerting should never exceed 5% by volume, and should normally be in the order of 2% to allow for uneven distribution. Much lower levels may be required for oxygen reactive cargoes (e.g. butadiene). The dew point temperature for the particular cargo to be loaded must be achieved during this operation

2. 置换(驱气):

1. 在对货油舱进行除气之前,必须用惰性气体对其进行吹扫,以将碳氢化合物气体含量降低到体积比 2% 以下。这将确保在除气过程中不会将货舱内空气的任何部分带入可燃范围。

2. 在装载某些化学品货物之前,为接收货物备舱。可能需要用氮气置换液货舱,以降低 O2 水平或置换先前货物中的气体含量。正常的船上惰性气体可能必须用纯氮气置换以满足货物要求(例如去除 CO2 或获得低露点)

PURGING:

1. Before cargo tank is gas freed, it must be purged with inert gas in order to reduce the hydrocarbon gas

content to less than 2% by volume. This will ensure that no portion of the tank atmosphere is brought within flammable range during gas freeing. ---ISGOTT

2. Prior to prepare tanks for receiving certain chemical cargoes, it may be necessary to purge the tank(s)

with Nitrogen, either to reduce the O2 level or in order to displace vapours from the previous cargo(s). Normal shipboard inert gas may have to be displaced with pure nitrogen for cargo requirements (e.g. to remove CO2 or to obtain a low dew point). ---Tanker safety guide

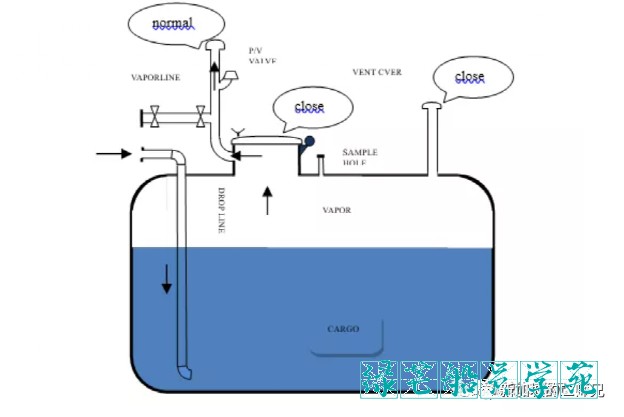

3.惰封/ 氮气填充:

出于货物质量控制和/或安全原因,在化学品油轮上使用氮气作为主要惰性气体。与货物装卸有关的氮气使用要求由 IBC 规则规定,用于货舱环境控制,或者当货物质量/客户需要时。

氮气惰封或填充用于在已经装满货物的货舱内建立正压,以防止在货舱冷却时空气或水进入,从而防止货物和水/空气之间可能发生危险反应/损坏。

PADDING / BLANKETING:

Nitrogen is used on Chemical Tankers as the primary Inert Gas for cargo quality control and / or for safety

reasons. The requirements for the use of nitrogen, in respect to cargo handling, are either dictated by the

IBC Codes for tank environment control or when the cargo quality / customers require it.

Nitrogen Blanketing or Padding is used to establish a positive pressure on a tank which has already been

filled with product in order to prevent the ingress of air or water as the tank cools and thus prevent a possible dangerous reaction / damage between the cargo and water/air.

负责人员必须监督惰封程序。值班人员必须确保所有未参与这些操作的人员都被限制在该区域外。

请注意,通过货物管线进行填充仅建议对低粘度货物(高粘度货物会有冒泡效应,瞬时发生压力过大),公司有要求货物年度大于50m.pas的时候不可以使用货管进行充氮,必须使用回气管线

A responsible Officer must supervise the blanketing procedures. The Officer in charge must ensure that all personnel not involved in these operations are restricted from the area. Note that padding via the cargo lines (bubbling through the high viscosity cargo, over pressure may happen) is only recommended for low viscose cargoes. Company has procedure for high viscosity cargo which more than 50 m.pas, Padding should be done from Vapor return line.

下面介绍 3 种不同的惰封方法的程序。惰封通常是在测量和取样后进行惰封

Following are procedures for 3 different methods of blanketing. Blanketing is to be carried out aftergauging and sampling

一. 装载后用开敞式进行惰封

开敞式惰封通常不会造成任何危险/危害,但必须注意以下事项:

Blanketing After Loading With Open Venting / Gauging, Blanketing after open venting will normally not

create any danger / hazards but the following care must be exercised:

1.在某些情况下,岸上将通过装载货物的同一软管/管线供应氮气。然后供应压力必须足以惰封货舱

中的一些液体压头加上 PV 设置。在这些情况下,必须在船岸安全会议期间讨论此信息。讨论应包

括岸上将采取哪些预防措施以确保操作是通过小软管完成的,并且速率不会超过货舱的通风容量。

岸上不能遵守的任何问题必须在操作进行之前提请管理层注意。

.In some cases the shore will supply the Nitrogen through the same hose / line through which the cargo

was loaded. Then supply pressure must be sufficient to cover some liquid head in the tank plus PV setting.

In these cases, this information must be discussed during the preload conference. The discussion should

include what precautions the shore will take to make sure the operation is done through a small hose and

that the rate will not exceed the capacity of the vent capacity of the tank cargo. Any problems with the

shore not being able to comply must be brought to the attention of the management Office before the

operation is carried out.

2. 必须注意避免货物从货舱中溢出。

Care must be taken that the cargo does not overflow from the tank.

二. 装载后,在封闭或通风受限环境下的惰封,无回气管

Blanketing After Loading with Controlled Venting / Closed or Restricted Gauging, Without Vapour Return

1. 在可能的情况下,在货舱上安装一个正负压力表(量程能覆盖PV阀工作压力)。在某些船舶上,

由货舱压力传感器组成的第二套透气系统将提供货舱压力的连续读数。

2. 将 P/V 阀排气盖置于手动打开位置(如果有)。

3. 船上自己做氮封,将 N2 供应软管连接到歧管或适用的货舱连接处的专用管线。

4. 在某些情况下,岸上将通过货物装载的同一软管/管线供应氮气。在这些情况下,必须在预加载

安全会议期间讨论此信息。讨论应包括岸上将采取哪些预防措施以确保操作是通过小软管完成的,

并且速率不会超过液货舱的排气能力。

在所有情况下,供应的氮气量(管线尺寸和压力参考 ICS 化学品油轮安全指南中的指南图表不大于

P/V 可以处理的量)都很重要。岸上的任何问题不能遵守的必须在操作前提请管理层注意。

5. 确保通往货舱的货物管路阀门打开。

6. 通过阀开度来控制氮气进舱量。初始时只开一点点。

7. 在惰封过程中密切监测货舱内的压力。

8. 当货舱内含氧量达到所需时,关闭氮气供应并关闭阀门。

9. 将 P/V 阀置于自动位置并关闭排气盖。

10. 如果需要正压,请慢慢重新打开氮气供应,密切监测压力。

11. 当达到所需压力时,关闭氮气供应并关闭所有阀门。

1.Where possible, fit a compound gauge to the tank (scale should cover the PV valve working pressure). On some vessels the secondary venting system consisting of tank vapour pressure sensor will provide continuous reading of tank vapour pressure.

2.Place the P/V-valve gas freeing cover in open position.

3.For ship supplied Nitrogen, connect N2 supply hose to cargo line at manifold or applicable tank connection.

4.In some cases the shore will supply the Nitrogen through the same hose / line which the cargo loaded. In these cases this information must be discussed during the preload conference. The discussion should include what precautions the shore will take to make sure the operation is done through a small hose and that the rate will not exceed the vent capacity of the cargo tank.

In all cases it is important that the volume of Nitrogen being supplied (size of the line and pressure refer to the guideline charts in the ICS Chemical Tanker Safety Guide is not greater than that which the P/V can handle. Any problems with the shore not being able to comply must be brought to the attention of the Management Office before the operation is carried out.

5.Ensure the cargo line valves to the tank are open.

6.Carefully open the valve controlling the Nitrogen supply. At initial stage only crack open.

7.Closely monitor the pressure in the tank during the blanketing.

8.When the required tank atmosphere is reached shut off Nitrogen supply and close the valves.

9.Place the P/V-valve in automatic position and close the gas freeing cover.

10.If a positive pressure is required, slowly re-open Nitrogen supply closely monitoring the pressure.

11.When the required pressure is reached, shut down the Nitrogen supply and close all valves.

三.装载后,在封闭或通风受限环境下的惰封,接回气管

Blanketing After Loading with Controlled Venting / Closed or Restricted Gauging, With Vapour Return

1. 在可能的情况下,在货舱上安装一个正负压力表(量程能覆盖PV阀工作压力)。在某些船舶上,

由货舱压力传感器组成的第二套透气系统将提供货舱压力的连续读数。

2. 确保蒸汽回流系统在整个惰封操作过程中保持打开状态。

3. 船上自己做氮封,将 N2 供应软管连接到歧管或适用的货舱连接处的专用管线。

4. 在某些情况下,岸上将通过货物装载的同一软管/管线供应氮气。N2 供应压力必须足以克服货舱

中的液体压力。在这些情况下,必须在预加载安全会议期间讨论此信息。讨论应包括岸上将采取哪些预防措施以确保操作是通过小软管完成的,并且速率不会超过液货舱的排气能力。

在所有情况下,供应的氮气量(管线尺寸和压力参考 ICS 化学品油轮安全指南中的指南图表不大于

P/V 可以处理的量)都很重要。岸上的任何问题不能遵守的必须在操作前提请管理层注意。

• 确保货舱联通的阀门打开

• 通过阀开度来控制氮气进舱量。初始时只开一点点。

• 在惰封期间密切监测货舱中的压力

• 当货舱内含氧量达到所需时,关闭氮气供应并关闭阀门。包括蒸汽回流系统(船舶阀门)。

• 如果惰封要求需要正压,则降低氮气供应压力。

• 缓慢关闭蒸汽回流阀

• 当达到所需压力时,关闭氮气供应并关闭阀门,包括蒸汽回流阀。

• 警告:切勿对液货舱过度加压(高于 P/V 阀设置)

1.Where possible, fit a compound gauge to the tank (scale should cover the PV valve working pressure). On some vessels the secondary venting system consisting of tank vapour pressure sensor will provide continuous reading of tank vapour pressure.

2.Ensure that the vapour return system remains open throughout the blanketing operation.

3.For ship supplied Nitrogen connect N2 supply hose to cargo line at manifold or applicable tank connection

4.In some cases the shore will supply the Nitrogen through the same hose / line which the cargo loaded. The N2 supply pressure must be sufficient to overcome liquid head in the tank. In these cases this information must be discussed during the preload conference. The discussion should include what precautions the shore will take to make sure the operation is done through a small hose and that the rate will not exceed the vent capacity of the cargo tank.

In all cases it is important that the volume of Nitrogen being supplied (size of the line and pressure refer to the guideline charts in the ICS Chemical Tanker Safety Guide is not greater than that which the P/V can handle. Any problems with the shore not being able to comply must be brought to the attention of the Management Office before the operation is carried out.

Ensure the appropriate valve(s) to the tank are open

Carefully open the valve controlling the Nitrogen supply

Closely monitor the pressure in the tank during the blanketing

When the required atmosphere is reached, shut off the Nitrogen supply and close the valves including the vapour return system (ship’s valve).

If a positive pressure is required upon competition of blanketing, reduce the Nitrogen supply pressure.

Slowly throttle down the vapour return valve

When the required pressure is reached, shut down the Nitrogen supply and close the valves including the vapour return valve.

WARNING: Never over pressurise a cargo tank (above the P/V valve setting)

对于2016年1月1号以后铺放龙骨的化学品船舶在卸货操作时是有特殊的要求,各位粉丝一定要仔细阅读,请遵守行业的要求。

化学品船的具体货物操作要求

§在化学品船上对货舱进行驱气或惰化,是为了在货物运输过程中避免反应或实现货物质量控制。货舱内的空距空间,以及相邻隔舱,可能也需要特别控制的舱气。

§化学品船大于等于 3,000 立方米的舱容,单个货舱配备大容量洗舱机(即喷嘴吞吐量超过 17.5 立方米/小时,洗舱剂排出大于 60 立方米/小时,或每个货舱的总水流量大于 110 立方米/小时)在这些货舱中运输低闪点化学品时需要使用N2 系统。对于装有化学品的小型货舱,IBC 规则中的最低要求摘要说明了出于安全原因需要进行哪些舱气控制(如果有)。此外,20,000 载重吨及以上载运石油货物的化学品船将需要对所有装有闪点不超过 60°C 的石油产品的货油舱进行惰化。当化学品船需要运输石油货物时,2016 年 1 月 1 日或之后铺设龙骨的船舶遵循 ISGOTT 关于惰性气体的建议。

§SOLAS 公约规定了惰性气体系统的配备。为了满足 SOLAS 对不可燃性的要求,惰性气体系统必须能够输送含氧量不超过 5%(体积比)的惰性气体以任何所需的流速下。该系统还必须能够始终保持液货舱内的正压,以使液货舱内的氧气含量不超过 8%(体积)。对于 IBC 规则要求在惰性条件下运输的货物,建议应遵守货舱中的最大氧含量限制在8%以下,除非另行规定了更低的含量。

§对于布置有基于废气(烟气)的惰性气体系统的液货船, 在装货、航行、卸货、油舱清洗和在空气除气前的驱气过程,必须进行惰化

§对于化学品船,可以接受惰化只需要在开始卸货前。据了解,该豁免条款被接受是为了减少货物操作时间(因为化学品船在装货前,商检总是会进行下舱验舱)。上述替代方案的一个非常重要的条件是氮气是唯一可接受的惰性气体介质。

§尽管在卸货开始之前不需要使用氮气,但在卸货、洗舱期间以及在用空气除气之前进行驱气时仍需要使用氮气。

Specific requirements applicable for chemical tankers

The reasons for cargo tanks to be purged or for cargoes to be carried under inert conditions on chemical tankers are to avoid reactivity or achieve cargo quality control. The vapour (ullage) spaces within cargo tanks, and in some cases the void spaces surrounding the cargo tanks, may require specially controlled atmospheres.

Chemical tankers with individual cargo tanks of 3,000m3 or bigger, or which have large capacity tank washing machines (i.e. with a nozzle throughput of more than 17.5m3 per hour, machine throughput greater than 60m3 per hour, or total water flow per cargo tank greater than 110m3 per hour) are required to use their N2 systems when carrying low flashpoint chemicals in these cargo tanks. For smaller tanks containing chemicals, the summary of minimum requirements in the IBC Code states what environmental control is necessary, if any, for safety reasons. Additionally, chemical tankers of 20,000 DWT and over carrying oil cargoes will be required to inert all cargo tanks containing petroleum products with a flash point of 60°C and less. When a chemical tanker is required to transport oil cargoes, the recommendations in ISGOTT about inert gas should be followed on or after 1st January 2016.

The provision and use of an inert gas system is specified by the SOLAS Convention.To meet the SOLAS requirements for non-flammability, an inert gas system must be capable of delivering inert gas with an oxygen content of not more than 5% by volume in the inert gas main at any required rate of flow. The system must also be able to maintain a positive pressure in the cargo tanks at all times, such that the tank atmosphere has an oxygen content of not more than 8% by volume. For cargoes which the IBC Code requires to be carried in an inerted condition, it is recommended that the maximum oxygen content limit of 8% in the tank atmosphere should be observed unless a lower figure is specified.

For tankers that are arranged with an exhaust gas based inert gas system, inerting must be

carried out during loading, on voyage, during unloading, tank cleaning and for purging prior to gas freeing with air.

For chemical tankers, it is however accepted that inert gas need only be applied before

commencing the unloading. It is understood that this exemption clause was accepted as a matter of convenience to reduce cargo handling time (as pre-loading procedures for chemical tankers always require in-tank cargo surveys). A very important condition for the above alternative is that nitrogen is the only accepted inert gas medium.

Although nitrogen does not need to be applied until before commencing the unloading, it is still required to be applied during discharging, during tank cleaning and for purging prior to gas freeing with air.

1. 航保的充惰要求

Handling Nitrogen during voyage

对货物惰封,必须根据收到商检的要求保持氮气的质量。对于某些货物,IBC规定惰封必须保持在正压下。除了任何监管要求外,一些托运人可能会对某些货物的运输提出自己的要求,如进行氮气惰封并保持正压。

每当船舶被告知需要在正压下保持惰封,在航行期间始终保持正压是非常重要的。When a Nitrogen blanket has been placed on a cargo, it is imperative that the quality of N2 and blanket is maintained according to instruction received.

For certain cargoes, the IBC codes specify that the blanket has to be maintained under positive pressure. Some shippers may, in addition to any regulatory requirement, set their own requirements for some cargoes to be carried with Nitrogen blanket under positive pressure.

Whenever a ship has been advised of the requirement for a Nitrogen blanket to be maintained under positive pressure, it is very important that the positive pressure is maintained always during the voyage.

PV Group

一、需要保持正压的航保

Nitrogen blanket with positive pressure

1.装货前,必须进行货舱气密性测试。2. 对于未配备远程压力读数(计算机化)的船舶,在读取压力读数时应使用压力表。3. 装载后立即惰封,必须立即密切监测压力一段时间,以验证货舱的密封性是否能保压。4、如果在维持正压方面遇到问题,必须进行彻底检查,如有泄漏,必须纠正。5. 当货舱和管线系统被确认紧密时,将启动/使用自动供氮装置。6. 氮气层的正压应始终保持在 50 mBar,除非承租人另有规定(P/V 阀通常设置为 200 mBar)。7. 定期(不超过 12 小时)读取并记录压力。在此期间,确保货舱和压力表之间的“截止阀”(如果在读数之间保持开启)关闭/固定。8. 每天更新氮气的消耗量、压力和 O2。1.Prepare for loading blanketing cargo, the cargo tank tightness test should be done before loading.

2.For ships not equipped with remote pressure readings (computerised), a pressure gauge (scale minus 0.5 to plus 1.0 bar) should be used when taking pressure readings

3.Immediately after placing the blanket after loading, the pressure must be closely monitored for a period to verify that the tank is holding the pressure.

4.If problems are encountered in maintaining the positive pressure, a thorough check must be carried out and any leaks must be rectified.

5.When the tank and line system are verified tight, then the arrangement for automatic feeding of Nitrogen is to be activated / utilised.

6.The positive pressure of the Nitrogen blanket should be maintained 50 mBar always, unless otherwise specified by the Charterer (P/V valves are normally set to lift at 200mBar).

7.At regular intervals, not exceeding 12 hours, take readings of and record the pressure. In the interim period ensure that the “shut off valve” between the tank and the pressure gauge (if remains on between readings) is closed / secured.

8.Record daily the consumption of Nitrogen, pressure & O2 log.

某轮进行HMD的航保

二、无需正压的航保氮封Nitrogen Blanket Without Positive Pressure

1. 惰封好后立即检查并记录空余空间环境(含氧量或露点)2. 如果航保指示无需保持O2或N2压力,则不要在航程中添加N2。3. 每天更新压力和 O2 记录。

Check and record the ullage space environment (oxygen content or dew point) immediately after the blanket has been put on after loading。If no instruction to maintain O2 or the pressure of N2, then do not to add N2 during voyage. Only Record daily the pressure and O2 log.

氮气瓶间

2. 卸货时,惰封保压注意事项,无连接回气管

Unloading, N2 operation precaution, without connecting vapour return line.

一、卸货中氮气的置换

根据IBC规则的规定需要对货舱气体进行特殊控制的货物在卸货时必须与岸上的接收罐进行蒸气回收或进行氮气置换,尤其要注意进行部分货物的卸载时也要确保满足了上述卸货作业的布置,无法提供上述布置时船长应拒绝卸货并咨询公司。对于为了保护货物质量且仅在客户的要求下进行氮封保护的货物,除非公司另有指示,否则应由客户或收货人安排有关的氮气置换或蒸汽回收。

如果码头无法提供蒸气回收时,船上必须按以下的要求进行操作,并且进行此项作业所需的氮气必须由岸上提供,该操作必须在负责驾驶员的监督下进行。

程序:

o确保货舱上安装了合适的压力表(-0.5—1.0巴)

o压力报警设定在P/V阀开启压力的90%

o如果在航行中使用了自动氮气供应装置,要将该装置与大舱的连接断开。

o将带有阀门的氮气供应软管与货舱或透气管线上合适的接头相连接。

o启动货泵之前,缓慢地打开氮气的供应阀,让大舱的压力慢慢的提升接近至P/V阀的设定值,密切监测大舱压力使其不超过P/V阀的设定值。

o查核上述的操作准确无误后,启动货油泵,慢慢地提高泵速和调整氮气供应量使卸货速度与氮气供应量相平衡。

o卸货速率达到最大后,调整氮气的供应量使大舱的压力保持在大概70毫巴左右。

o在整个卸货过程中,密切监测货舱的压力,确保卸货速度同氮气的供应一直保持平衡。

o卸货完成后,如果要求,应确保在整个洗舱过程中货舱的大气环境控制一直在保持。

Nitrogen Displacement During Discharge

Cargoes that require specially controlled atmosphere according to the IBC code must be discharged with either vapor return from the receiving tank or by N2 displacement. Particular care must be taken when a part discharge is to take place to ensure arrangement for above described condition is provided for. Failure to provide such arrangement should result in the master refusing to commence cargo operations and calling the company for advice. For cargoes that have been carried under a N2 blanket for quality reasons and as a customer requirement only, the arrangement for N2 displacement or vapor return will be dictated by the customer/receiver unless otherwise instructed by the company.

When vapor return cannot be provided for, the following must be adhered to, and the nitrogen required for this operation must be supplied from shore (terminal). This operation must be supervised by a responsible Officer.

PROCEDURES:

Ensure a suitable pressure gauge is placed on the tank (scale minus 0.5 to plus 1.0 bar).

Pressure alarm shall be set to 90% P/V valve setting pressure.

Disconnect the Automatic Nitrogen Feeding system, if used during the voyage.

Connect Nitrogen supply hose with valve to the appropriate connection on the tank or

vent line system.

Before starting the cargo pump, slowly open the Nitrogen supply and allow pressure to

gently build up to the lifting pressure of the P/V-valve. Closely monitor that the pressure

does not exceed the setting of the P/V valve.

When proper operation of above-mentioned is verified, start the cargo pump and slowly

increase the speed simultaneously as adjusting the nitrogen supply to balance the pumping

rate.

At full pumping rate, adjust the nitrogen supply to maintain an overpressure of approx

imately 70 millibar.

Closely monitor the tank pressure during the entire discharge operation to ensure that

balance is always maintained between the pumping rate and the nitrogen supply always.

Upon completion of the discharge, ensure that the controlled tank environmental is

maintained throughout the cleaning operation, if so required.

二、惰气供应故障的处理

遇到的问题:无法提供所需数量和质量的惰性气体

无法保持货油舱内的压力

惰性气体系统停止运行

必须立即采取措施防止空气被吸入舱内。必须停止所有卸货、卸压载、洗舱、空距测量或取样,并且必须关闭惰性气体甲板隔离阀。

如上所述,在惰性气体装置恢复正常和舱内惰化达标。尽快将 IGS 故障通知公司。与公司保持有效的实时沟通,直到故障原因得到纠正。

在咨询公司后,如果 N2 系统故障无法马上恢复,船舶将被指示通知货操和/或承租人,以获取替代惰化装置,例如 N2 瓶、岸方供应的氮气。又如船对船作业中,其他船舶提供的 N2 供应。

如果无法及时采购替代惰化装置,船舶应进行非常规风险评估,以符合 ISGOTT 的所有建议,并且在获得公司和货操和/或承租人的批准之前不得重新开始货物作业。

货舱涂层通常会抑制成品油船货油罐中自燃物的形成。如果认为 N2 系统完全不可恢复,则可在所有相关方的书面同意下恢复卸货,前提是提供外部 N2 供应或制定详细程序以确保操作安全。

In the event of inert gas system failure,

• Inability to deliver the required quantity and quality of inert gas

• Inability to keep up pressure in the cargo tanks

• Shut down of the inert gas plant

Immediate action must be taken to prevent any air being drawn into the tanks. All discharging, deballasting, tank washing, ullaging or sampling must cease and the inert gas deck isolating valve must be closed.

Cargo operations, as above, must not be recommenced until the inert gas plant is returned to service and tanks are satisfactorily inerted. Office to be informed as soon as practicably possible about the IGS failure. Effective real time communication to be kept with the office till cause of failure has been rectified.

After consulting the office and in case N2 system failure cannot be rectified vessel will be

instructed to inform commercial operators and/or charterers in order to procure alternative inerting arrangements such as N2 bottles, N2 supply from shore or other vessel in case of STS or double banking operations]. If alternate inerting arrangements cannot be procured the vessel shall carry out a non-routine risk assessment in order to comply all recommendations as per ISGOTT and shall not recommence cargo operation prior obtaining approval from the office and commercial operators and/or charterers.

Tank coatings usually inhibit the formation of pyrophors in the cargo tanks of product tankers. If it is considered totally impracticable to repair the N2 system, discharge may therefore be resumed with the written agreement of all interested parties, provided that an external source of N2 is provided or detailed procedures are established to ensure the safety of operations.

保证以下预防措施:

应查阅船舶特定的 N2 手册。

防止火焰通过的装置或防火网(视情况而定)已就位,并且检查以确保它们处于良好状态。

不允许舱口围作业

不得将量舱、量空距、取样或其他设备导入货舱,除非是本质安全的设备和操作。

如果实在需要将此类设备导入货舱,则应在惰性气体注入停止后,至少静置 30 分钟后进行。

将导入货舱的任何设备的所有金属部件都应安全接地。

此限制应一直应用到惰性气体注入停止后 5 小时。当洗舱作业在非惰化环境下进行,所有预防措施都应按照 ISGOTT 和 IMO 惰性气体系统出版物的指南进行。

The following precautions should be taken:

- The ship specific N2 manual should be consulted.

- Devices to prevent the passage of flame or flame screens (as appropriate) are in place and are checked to ensure that they are in a satisfactory condition.

- No free fall of water or slops is permitted.

- No dipping, ullaging, sampling or other equipment is introduced into the tank unless essential for the safety of the operation.

- If it is necessary for such equipment to be introduced into the tank, it should be done after at least 30 minutes have elapsed since the injection of inert gas has ceased.

All metal components of any equipment to be introduced into the tank should be securely earthed.

This restriction should be applied until a period of five hours has elapsed since the injection of inert gas has ceased. When carrying out tank cleaning in non-Inert atmosphere all precautions to be used as per ISGOTT and guidance as per IMO publication on Inert gas systems.

- 发表于 2023-04-24 19:52

- 阅读 ( 3289 )

- 分类:海员培训

你可能感兴趣的文章

相关问题

0 条评论

文件生成中...

请稍候,系统正在生成您请求的文件

化学品船氮气操作

扫码过程中请勿刷新、关闭本页面,否则会导致支付失败

购买后请立即保管好,30天后需重新付费。

化学品船氮气操作

扫码过程中请勿刷新、关闭本页面,否则会导致支付失败

购买后请立即保管好,30天后需重新付费。

请点击下载或复制按钮进行操作