应急消防泵吸入管在机舱内要求

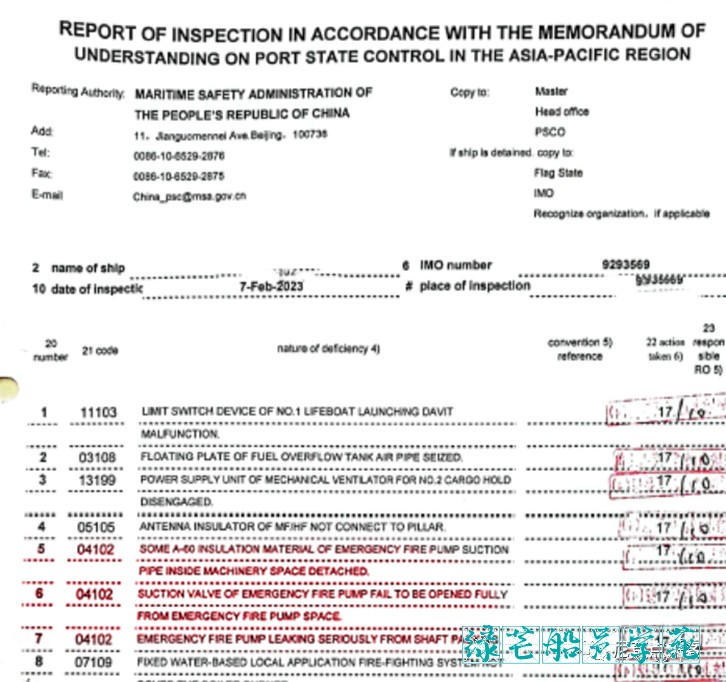

最近一艘船舶在国内进行PSC例行检查,PSCO签发多条缺陷,其中有3条与应急消防泵有关。 船舶救生消防是船舶安全最后一道安全防线,无论是任何检查与审核,都是关注重点,那我们讨论一下第5条关于应急消防泵吸入口在机舱时如何处理。

我们看看公约原文

SOLAS chapter II-1 Reg 10 2.1.4.1 Isolating valves to separate the section of the fire main within the machinery space containing the main fire pump or pumps from the rest of the fire main shall be fitted in an easily accessible and tenable position outside the machinery spaces. The fire main shall be so arranged that when the isolating valves are shut all the hydrants on the ship, except those in the machinery space referred to above, can be supplied with water by another fire pump or an emergency fire pump. The emergency fire pump, its seawater inlet, and suction and delivery pipes and isolating valves shall be located outside the machinery space. If this arrangement cannot be made, the sea-chest may be fitted in the machinery space if the valve is remotely controlled from a position in the same compartment as the emergency fire pump and the suction pipe is as short as practicable. Short lengths of suction or discharge piping may penetrate the machinery space, provided they are enclosed in a substantial steel casing, or are insulated to A-60 class standards. The pipes shall have substantial wall thickness, but in no case less than 11 mm, and shall be welded except for the flanged connection to the sea inlet valve.

便于阅读,把此条翻译中文如下

2.1.4.1 用于将布置在设有主消防泵或泵组的机器处所内的消防总管部分与消防总管其他部分分开的隔离阀,应设在机器处所之外易于到达并站得住的位置。消防总管应布置成当

隔离阀关闭时,船上除上述机器处所内的消火栓外,其他所有消火栓能由另1台消防泵或1台应急消防泵供水。应急消防泵及其海水入口、吸水以及送水管和隔离阀应位于机器处所的外部。无法做到这种布置时,如对该阀门进行遥控的位置与应急消防泵在同一舱室,可在机器处所安装通海阀箱,吸水管要尽可能短。吸水管和排水管的一小部分可以贯穿机器处所,但应由坚固的钢质外套包裹,或隔热至“A – 60”级标准。管子应有足实的壁厚,无论如何不得小于11 mm,并且除与海水进口阀门的连接采用法兰外,所有接头均应采用焊接连接。

目前常用做法

应急消防泵无论是布置在船尾还是船头,其吸入口尽量避免在机舱。若实在布置不可行,尤其是一些小吨位船舶,不可避免有一部分通过机舱,那就要按照以上条款执行。通用做法是用A-60材料进行包扎,管路中间不能有法兰,管壁厚度不小于11mm。

- 发表于 2023-04-28 05:25

- 阅读 ( 841 )

- 分类:海员培训

你可能感兴趣的文章

相关问题

0 条评论

文件生成中...

请稍候,系统正在生成您请求的文件

应急消防泵吸入管在机舱内要求

扫码过程中请勿刷新、关闭本页面,否则会导致支付失败

购买后请立即保管好,30天后需重新付费。

应急消防泵吸入管在机舱内要求

扫码过程中请勿刷新、关闭本页面,否则会导致支付失败

购买后请立即保管好,30天后需重新付费。

请点击下载或复制按钮进行操作